From complex to controlled

Any questions?

Tommi Penttilä

Sales Manager Conventional Power

Phone. 0207 416 208

Mob. 040 512 2308

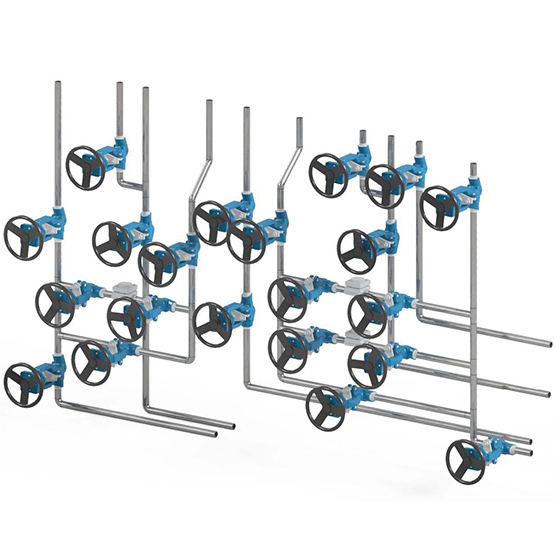

Prefabrication simplifies installation

Need

The combined heat and power plant initially contacted Askalon AB regarding the possibility of supplying shut-off valves for their two existing turbine drainage systems. The scope involved 42 high-pressure shut-off valves and six steam traps, divided across twelve drainage lines from two turbines. During further discussions about the customer’s problems with leakage from the valves and increased maintenance, it was also revealed that the pipelines for the drainage system had reached the end of their lifespan and needed to be replaced. The customer had planned to install welded valves as part of a site-built piping assembly, where all valves and other products would be welded and assembled during a scheduled shutdown.

In addition to extensive welding assembly, there would also be a need to engage consultants to develop manufacturing and installation documentation. The need for internal coordination of multiple contractors, both before and during the maintenance shutdown, would also place a burden on the internal organization.

Solution

Askalon AB presented a more efficient solution and proposal to the customer where the turbine drainage system would be prefabricated in modules. These modules would be assembled and tested in our workshop facilities in Hammarö. A total of over 100 welds would be transferred from on-site construction to prefabrication, also relieving the internal organization before and during assembly. This approach also simplifies quality control to ensure compliance with the pressure vessel directive's requirements for welding, heat treatment, non-destructive testing, and thee intended function for the application. By purchasing the module at a fixed price, the customer increased the predictability of the total installation cost. The reduced number of tasks during the maintenance shutdown provides greater control over the schedule, working conditions, and the quality of the finished result. The existing drainage system had an unsatisfactory design, with two systems having different design data run crosswise. The design was also not service-friendly, with poor access to the drainage valves. Askalon was able to contribute to an improved design without changing the scope or significantly increasing the cost of the prefabrication.

Proven industrial improvements

- Improved access for maintenance work.

- Reduced need for leakage testing and increased confidence in the installation.

- Downtime for installation could be kept to a minimum as prefabrication was performed.

- Lower maintenance costs.

- Limited use of internal resources.